Turn-key product development

Sealing Technology requires a thorough description of the application, its environment and the dynamic and static forces working on the sealing element. Enjoy our know-how and experience and invite us to study your application, discuss the application with your engineers and set-up a framework to realise a suitable sealing solution!

CREATIVE DESIGN

In search of the best design for your sealing solution, we bring together our experiences and those of our partners.

Product

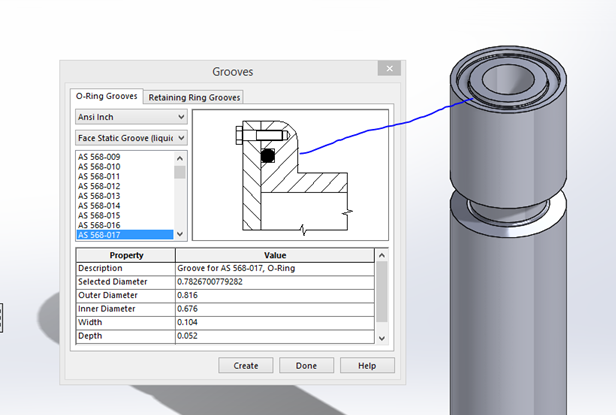

A wide variety of sealing components is available in the market. Based on our framework of requirements, a selection is made to determine the most suitable type of sealing component.

Added Value Services

To optimise the well-functioning of Sealing components, it can be necessary to have the parts treated before shipment or to have the packed in a specific way.

…Before anything else, preparation is the key to success.

SealTec specialises in Sealing Technology. Next to our standard parts and your design parts, we engineer new sealing components in close cooperation with your organisation.

Together with your engineers we set up a plan to engineer a suitable seal or gasket. We discuss the application. Environmental influencers like media, temperature and pressure are determined. And the location of the seal within the application is thoroughly described. Counter parts of the seal are evaluated. All information is gathered as the basic information for our action plan.

In the following steps of the action plan, suitable materials are determined and sketches of applicable seals are made. In close cooperation with production the producibility of the design in combination with the suitable material is discussed. Where necessary, the design is modified. Depending on the application and the requirements in practice, FEA analysis will be used to determine the forces and pressures on the seals. All information is gathered in a well documented report describing all the steps that led to the new seal or gasket.

SealTec is part of a strong network of manufacturing companies. All our partners comply with the ISO 9001-2015 quality management system. Most of them also hold certifications according IATF 16949:2016, AS9001D (aerospace industry) and ISO 13485 (medical industry). This strong supplier base offers you a wide variety of materials and designs to fulfil the demands of our action plan!

We offer to you

Sealing Technology is our passion. Above all, you will find with us the enthusiam and desire to offer you the most suitable solution for your application!

In the table below you find an overview of the products, designs and materials available to us.

- NBR, HNBR, EPDM, FKM

- Silicone materials

- CR, SBR, IIR

- Fluorsilicone FMVQ

- FKM GLT of GF

- Perfluorelastomers (FFKM)

- Self-lubricating materials

- Metal detectable materials

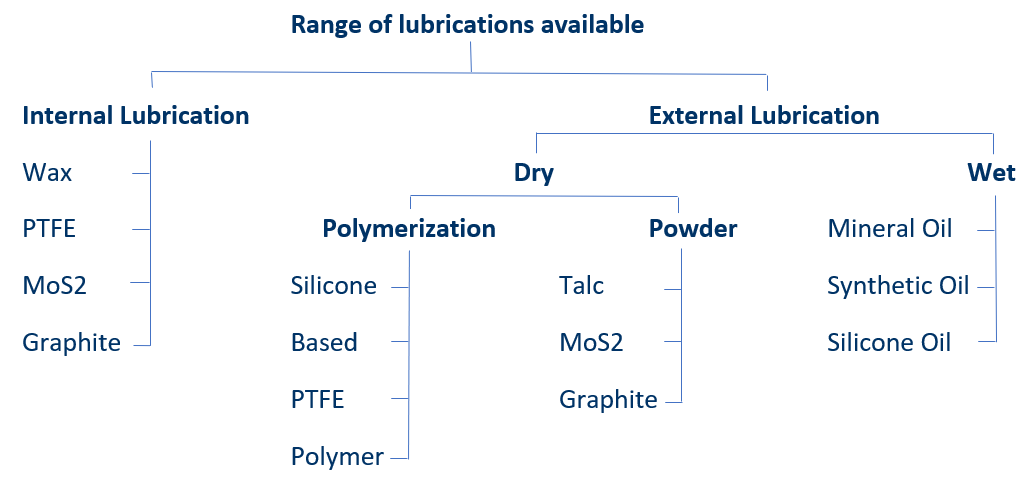

For some applications it is necessary to modify the standard “behavior” of the elastomer. E.g. the standard friction can be too high, mounting of the component can be to hard or distinction between other components can be too hard. In many of these situations a specific coating can offer a suitable solution.

Due to the increasing number of guidelines and regulations, parts and/or materials need to be provided with an approval or certificate. Within our portfolio we hold a long range of materials that suit these applications. And if your application demands for new materials a development program is set-up with our compounders to meet the requirements.

We see it as our job to provide you with a complete product, supplied with the corresponding documentation to satisfy your customers and inspectors.

You may choose from a long list of materials and approvals. Please find the most frequently used approvals below:

- Food & Beverage NSF, FDA, EC1935:2004

- Drinking Water KTW, WRAS, ACS, W270

- Pharmaceutical USP Class VI

- Gas EN549, EN682

- LPG and LNG R67, R110 and UL157

- Flue Gases EN14241-1

- Oil & Gas NORSOK M-710 Revision 2

- Semiconductor Cleanliness Regulations

- Others