semi-metallic gaskets

Semi-metallic gaskets are widely used in various industries. This sealing devices is a combination of both metallic and non-metallic components. While the metallic component gives the semi-metallic gasket strength, the non-sealing component ensures a superior sealing.

spiral wound gaskets

SealTec spiral wound gasket (SWG) consists of thin metal hoop and nonmetal filler material that are simultaneously wound. The metal hoop is pre-formed in V or W shaped profile, which allows the gasket to act as a spring between the flanges. The hoop also provides the basic structural element for the gasket while the nonmetal filler material seals the flange surfaces that are with small imperfections. Depending on its excellent compression resilience, it is very suitable for sealing spots where the alteration of temperature and pressure are frequent. It can be used as the static sealing element of pipe, valve, pump, thermal exchange, condensing tower, plain hole, man hole of flange, etc. It has been widely applied in the fields of petrochemical, mechanical manufactory, power station, metallurgy, shipbuilding, pharmaceutical, nuclear power station, and navigation.

Materials:

Metallic material (hoop): SS304 (standard) , SS304L, SS316, SS316L, 321, 317L, etc.

Non-metallic layer (filler): Flexible graphite, PTFE, non-asbestos material, Ceramic etc.

Inner & outer ring: Carbon steel (standard), SS304, SS304L, SS316, SS316L, 321, 317L, etc.

Thickness:

Thickness gasket: 3.2mm, 4,5mm (0,175”) 6.4mm.

Thickness inner & outer ring: 2mm, 3mm (01,125”), 4mm.

Service Limits:

Depending on the layer material, the gaskets can resist temperature up to 1000°C.

Maximum sealing pressure: Depending on the filler material and the service conditions the pressure resistant is >300bar.

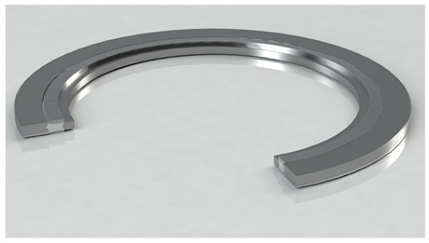

Kammprofile gaskets

Sealtec Kammprofile gasket consists of a metal core with concentric grooves on both sides. A sealing layer is usually applied on both sides and depending on the service duty the material for the layers can be graphite, PTFE, or other soft materials. The non-metallic layers protect the flange surface from damage in addition to providing an excellent seal at very low bolt stress.

Applications: It is the preferred gasket when improved performance at low seating stresses is required, particularly suitable for applications where high temperatures, pressures and fluctuating conditions are encountered. It is the ideal replacement for problem applications associated with jacketed gaskets, for heat exchangers, vessels, reactors and various flange connections.

Materials: Metallic core: carbon steel, SS304, SS304L, SS316, SS316L, etc.

Non-metallic layer: flexible graphite, PTFE, non-asbestos material, etc.

Service Limits: Depending on the layer material, the gasket can resist temperature up to 700°C. Maximum sealing pressure: >250bar.

Dimensions: The gaskets can be manufactured in various shapes and sizes upon request.

Thickness of metallic core material: generally in 3mm but for gaskets with diameter above 1.5m it is suggested in 4mm.

Thickness of non-metallic layer material: generally in 0.5mm on each side.

Normal cam pitch: 1mm

Groove depth: 0.4mm.

Alternative profiles are available on request, e.g. cam pitch: 1.5mm, groove depth: 0.6mm